Cable Hoists

Featured Model

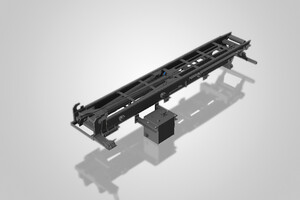

American Roll-Off—ARH

- Heavy-Duty Capacity: Can handle loads up to 75,000 lbs

- Versatile Models: Available in various configurations to suit different applications

- Durability: Designed for longevity and safety, with over 45 years of manufacturing experience

- Made in the USA: Proudly manufactured in Trenton, New Jersey

- Innovative Design: Includes features like low clearance, standard application, frame clearance, and heavy-duty options

EXCLUSIVE MODELS

designed for your needs

STRENGTH, LONGEVITY AND SAFETY

- Wide Range of Capacities: From 12,000 to 75,000 lbs

- Certified Welding: AWS D1.1 standard certified quality welding

- Larger Sheaves: 10-12" sheaves on 60-75k Rolloff models for longer cable and bushing life

- Patented ICC Bumper: Automatically folds when the hoist is raised

- Extendable Tails: Allow for lower loading heights and are Federal DOT compliant

Available Now

AWS D1.1 Certified Welding

There is a lot of welding on a cable hoist, but not all welding is created equal! Trust in our AWS D1.1 standard certified quality welding.

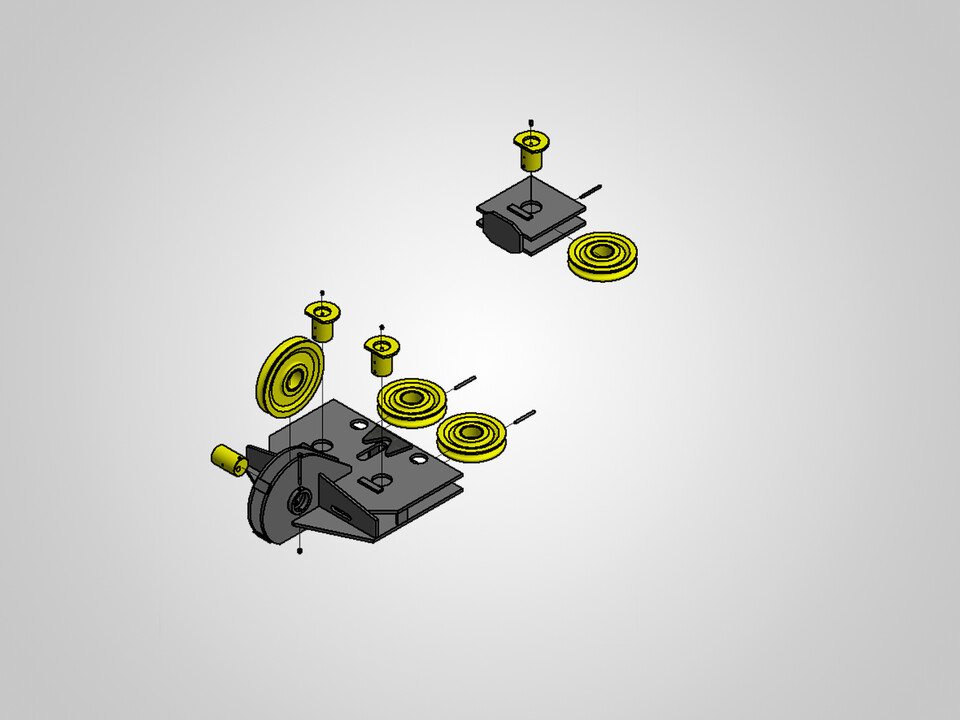

10-12” Cable Sheave

On any 60-75k Rolloff, we utilize a 10-12” Sheave, not an 8” as many competing products do. A larger sheave is much easier on the cable and bushings leading to longer life.

Patented Folding ICC Bumper

Our patented ICC bumper automatically folds when the hoist is raised without the added complexity of another air valve or active mechanical pivots.

Extendable Tail Models

Extendable Tails allow for lower loading heights assisting in sensitive areas. All of our extendable tail hoists are Federal DOT compliant; many in the industry are not with 22’ or 24’ containers. Under hoist tail cylinder eliminates the need for an extra idler pulley due to reeving cylinder spacing.

Uptime is key

Jeffrey Matz, Operations Manager—Tri-State Waste & Recycling

PALFINGER keeps us up and running. It’s a reliable hoist. Everything we get at PALFINGER meets our needs and meets our customer’s needs to provide a quality product.