Hookloaders

For more than 40 years, PALFINGER offers solutions for the specific needs of its customers throughout the world.

The functional design of our hookloaders and skiploaders ensures simple use and low maintenance. We offer a durable product and good operational profitability of your equipment.

Our cutting-edge hook lift enables roll off and roll on operations that is smooth and highly machine assisted with rear cameras available for seamless container handling. Streamline your waste management and material handling operations with Palfinger hooklift solutions. Upgrade for efficiency today!

System monitoring

The option has been developed to allow a better control of operations from inside the cab. Drivers can see accurately and without effort, what they are doing. They can adjust their handling at the right moment saving time without compromising safety

PALFINGER CONNECTED

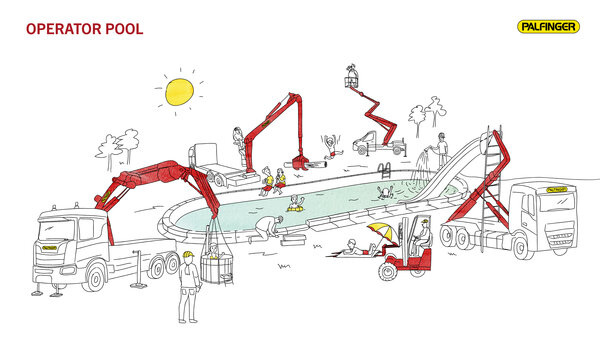

Efficiency for fleet, truck and hookloader - we support you in modern fleet management with efficient digital platforms, optimzied for fleet managers, operators and service partners.

Time saver – Advanced Rapid Motion

The advanced rapid motion option increases the performance and saves time during container handling. More daily rotations are possible with less dead time and drivers avoid blocking the location for longer than necessary. It reduces the cycle time by enabling high speed operation while extending (-50%) and retracting (-30%) cylinders.

Soft sliding

This feature enables silent and smooth loading.

Thanks to the reinforced polyamide sliders, the box slides more smoothly. Operation is more comfortable for the driver and his environment.

OSS - One Stop Shop

One stop Shop allows standardized bodybuilding within our network, while more reliable completion date.

POP - PALFINGER Origin Protection

The main components are sand-blasted, degreased, primer painted and final coated (according to customer specification) before assembling, all other parts are zinc nickel anticorrosion treated (meets ISO 12944 standard specifications concerning surface protection, classification 3).