Small

PC 2700 Compact

- Go back

- Home

- Products

- Loader Cranes

- Models

- PC 2700 Compact

PC 2700 Compact

Compact lightweight solutions between one and four metre tonnes with real PALFINGER power

- High value retention thanks to coating technology

- Optimum protection thanks to internal oil ducts in the extention cylinders

- Load holding valves prevent the crane boom from dropping

- Extended range of applications thanks to the optional radio remote control and cable winch"

Experience the product features

KTL

PRODUCT FEATURES

The right surface treatment is the foundation for durable and long-lasting surface protection. The components pass through the priming and painting process stages fully automatically. Through this innovative technology for surface coating, PALFINGER creates a quality standard that is usually only found in the automobile industry.

HOW IT WORKS

1. The crane components are cleaned of all impurities by means of cut steel shot blasting.

2. The components are degreased, rinsed, activated and coated with zinc phosphating in the individual immersion tanks.

3. After two additional rinsing processes, the surfaces are passivated as well as rinsed with ultra-pure water.

4. The electrostatic cathodic dip painting follows by immersing the crane components completely in the paint.

5. Excess paint is washed off in two additional operations with an ultra-filtration rinse.

6. Afterwards, the paint is cured at a temperature of 115 degrees for 1.5 hours.

7. At the end, the crane components are given a water-soluble, environmentally friendly two-component finish coat of paint by a painting robot.

Radio Remote Control

PRODUCT FEATURES

Today, radio remote controls are often considered to be standard equipment when it comes to modern loader cranes. PALFINGER radio remote controls are equipped with a choice of a linear lever or cross lever and provide the greatest possible comfort of the operator. For cranes with PALTRONIC an LCD graphic display or 4.1 inch TFT- colour display informs the crane operator of the different operating conditions.

HOW IT WORKS

The remote control console (transmitter) is responsible for transmitting the commands made on the levers to the receiver. The receiver forwards the signals to the electronics, which convert them into crane movements by means of hydraulic control valves.

*Optional feature/country-specific-equipment

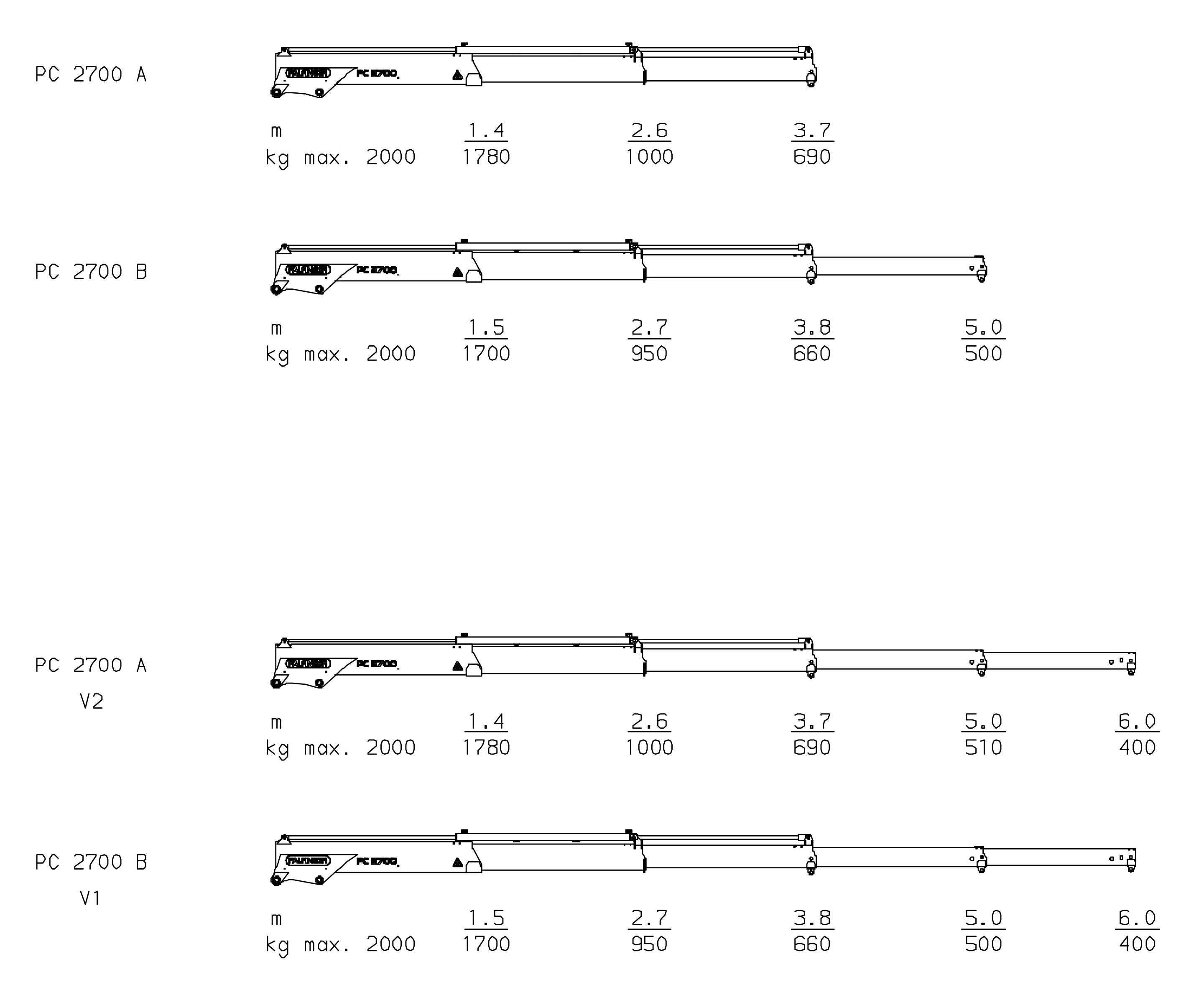

| Max. lifting moment | 2.6 mt |

| Max. lifting capacity | 2000 kg |

| Max. hydraulic outreach | 5.0 m |

| Max. manual outreach | 6.0 m |

| Slewing angle | 325° |

| Slewing torque | 0.3 mt |

| Max. operating pressure | 200 bar |

| Pump capacity | 9 l/min |

| Dead weight (std) | 216 kg |

Cranes shown in the leaflet are partially optional equipped and do not always correspond to the standard version.

Country-specific regulations must be observed. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

|

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|

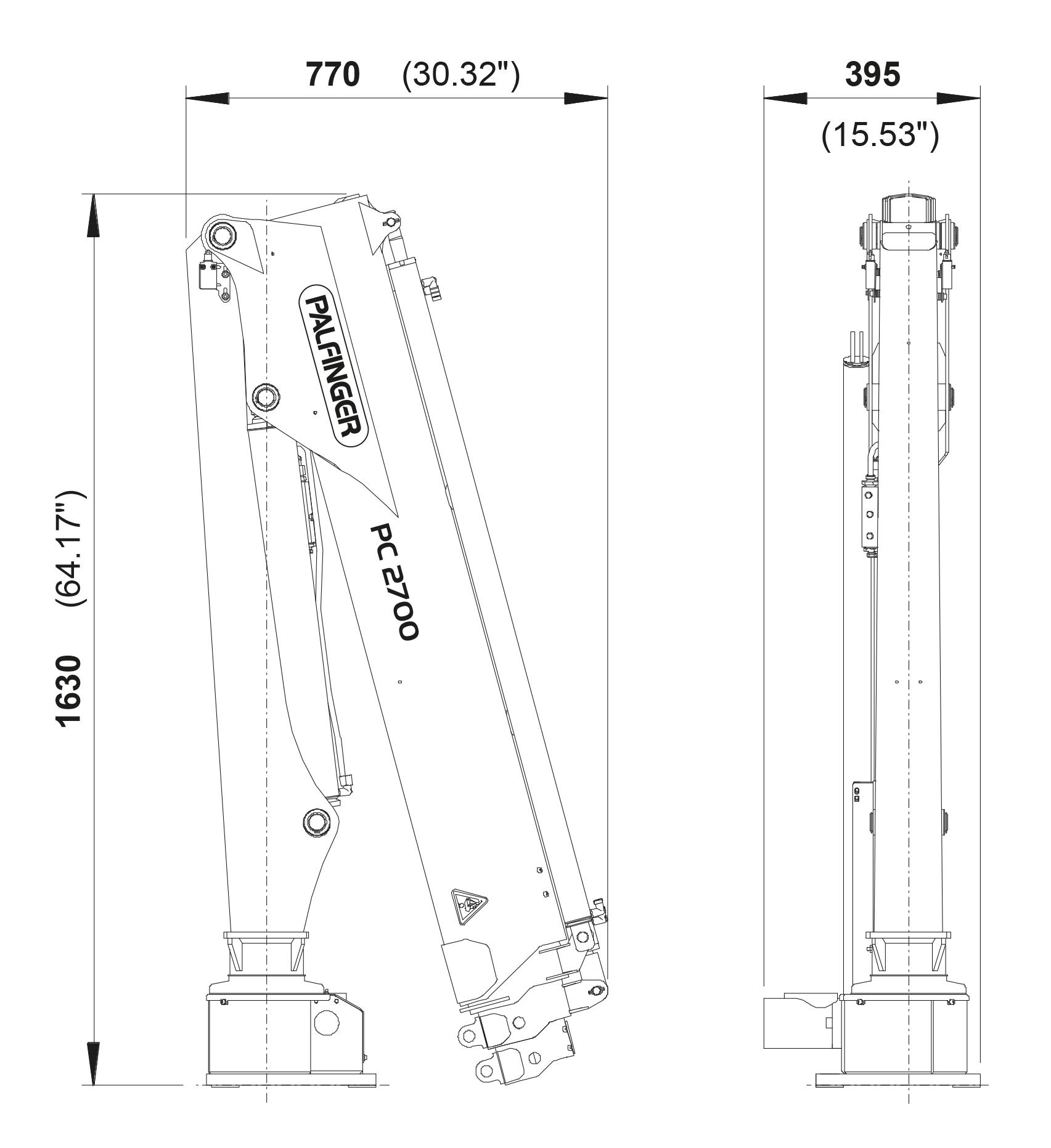

| A | 2.6 | 3.7 | 325 | 0.3 | 20.0 | 9 | 207 | 1630 | 770 | 395 |

| B | 2.5 | 5.0 | 325 | 0.3 | 20.0 | 9 | 228 | 1630 | 770 | 395 |

The outreaches stated are with a boom angle of 20° and are therefore not the maximum. When using mechanical boom extensions, the loads shown on the charts need to be reduced by the weight of these extensions.

PALFINGER SERVICES

Brochures

You are currently on the PALFINGER Europe page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?